THERM-CONNECT

WOLF Circuit Compound Systems

Top-Class KVS

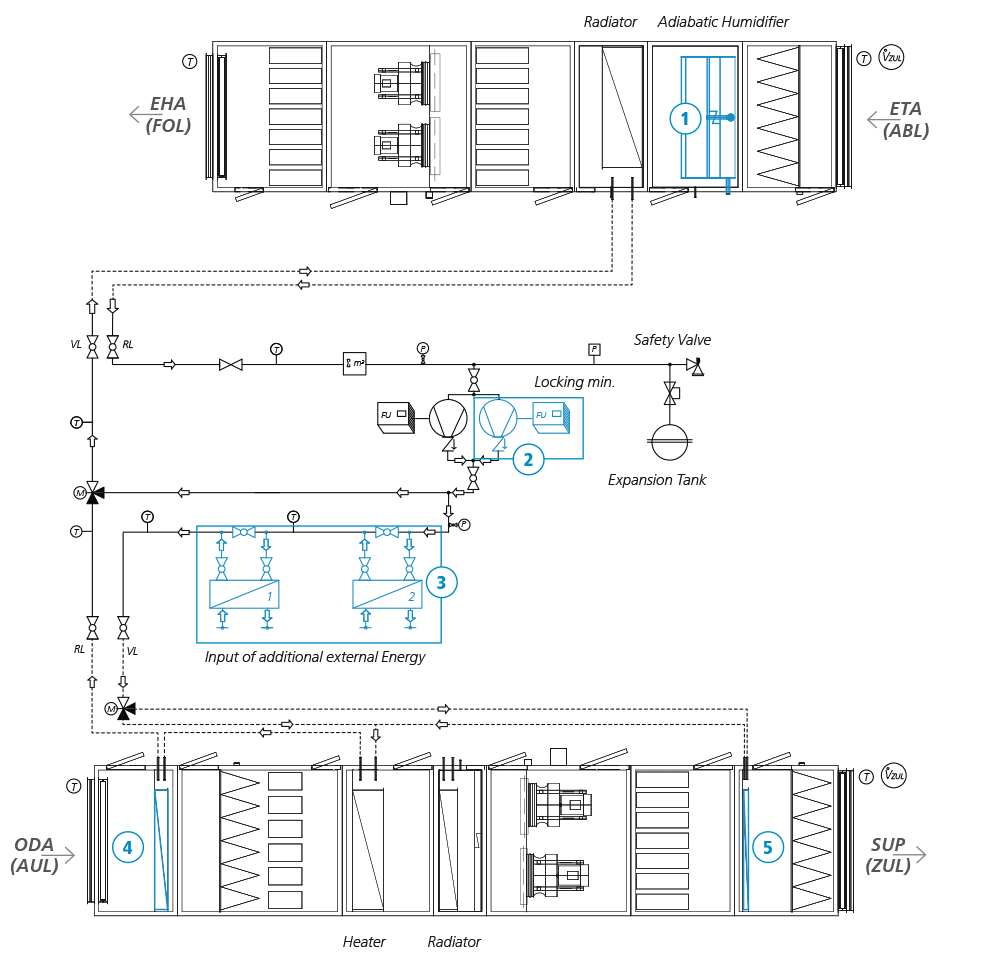

THERM-CONNECT systems by WOLF enable an efficient transfer of heat or cold without mixing the air flows. Es-pecially for projects in hygiene zones or limited space (for example reconstructions), THERM-CONNECT is the ide-al choice. Thus, you will meet all relevant legal standards and guidelines (ErP 2018, DIN EN 116, VDI 6022 etc.), providing a sustainable system.

Advantages

- Efficient heat and cold recovery

- Energy-optimized control system according to existing air flow

- Continuous efficiency optimization by inherent control programming

- Expansion tank for constant pressure conditions

- Remote monitoring and GLT-control by BACnet, Modbus etc. (optional)

- Integrated frost protection (optional)

- Rating of heat exchangers and hydraulic unit as requested by customer

- Complete housing cube with collecting tray (optional)

- Project-specific adjustment of housing cube possible

- Additional heat / cold feeding (optional)

- Adiabatic exhaust air humidification for increased cold recovery (optional)

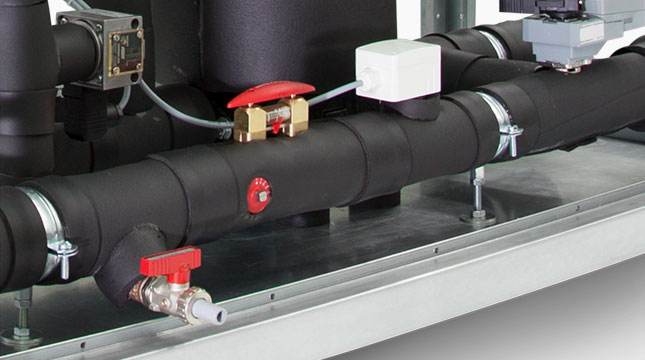

- System insulation with Armaflex (optional)

- Piping in high-grade steel (optional)

- Redundant double pump (optional)

- Weatherproof housing for outdoor installation (optional)

Integrated control system

High-performance filter

High-grade insulation

Quality Guarantee

THERM-CONNECT combines high-grade components, efficient control system and intelligent protective mechanisms (frost protection, overpressure protection), guaranteeing a performance that meets your needs, highest safety and efficiency as well as compliance with all relevant standards and guidelines.

THERM-CONNECT is being used throughout the year

Heat transfer in winter and cold transfer in summer

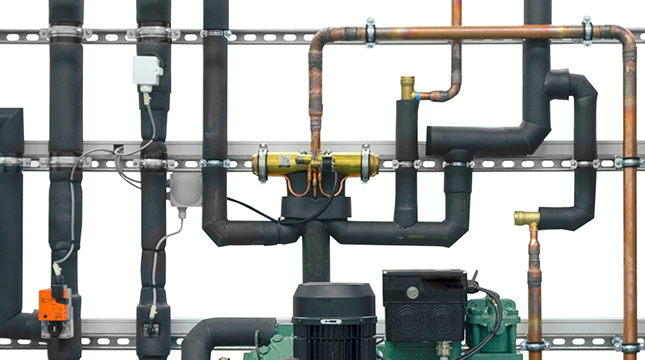

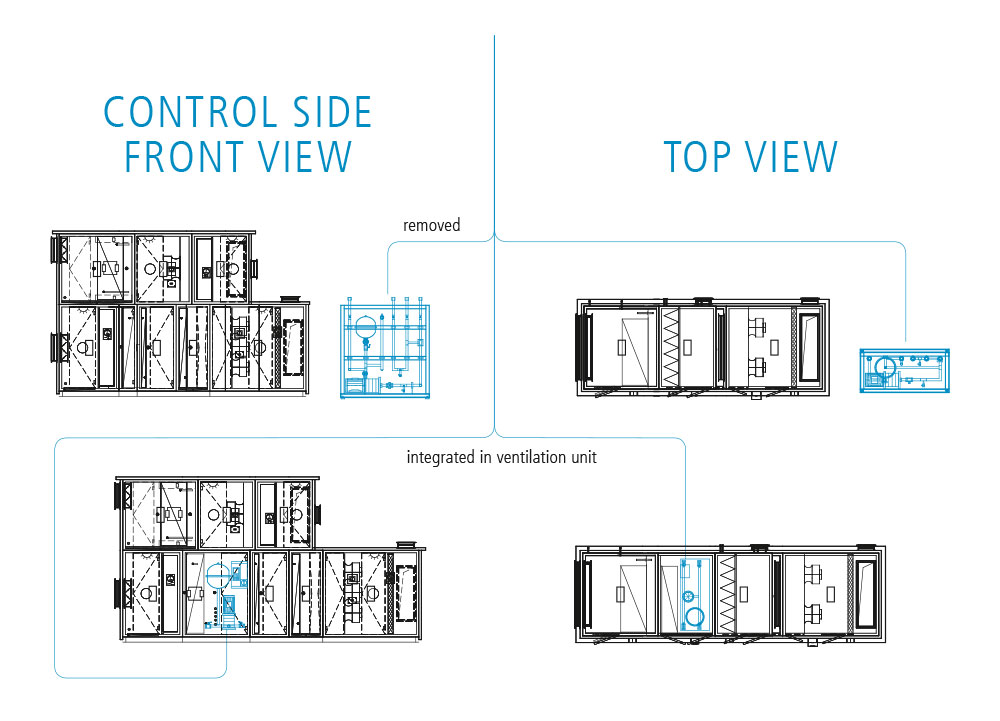

WOLF hydraulic modules make it possible. The air inlet and outlet registers separated from each other are connected hydraulically by a water-glycol mixture, which is transport-ed by an energetically optimized high-pressure centrifugal pump.

The high-performance registers

working with high counterflow exposure and a reactivation of the single heat transfer steps provide maximum efficiency. Depending on type and requirements, our hydraulic modules can be installed flexibly as separate housing cube or in the ventilation unit.

| Denomination |

THERM CONNECT - basic |

THERM CONNECT - defrost |

THERM CONNECT - magna |

| Pump |  |

|

|

| Frequency converter |  |

|

|

| Control ball valve |  |

|

|

| Insulation of components (optional) |  |

|

|

| Integrable into ventilation unit |  |

|

|

| Easy control (0 – 10 V) |  (Control valve) (Control valve) |

|

|

| Frost protection |  (1/2“ sleeve) (1/2“ sleeve) |

|

|

| Temperature sensors on water side |  |

|

|

| BACNet, Modbus etc. |  |

|

|

| Flow sensor |  |

TacoSetter | Electronic sensor |

| Energy-optimal control system |  |

|

|

| Collecting tray | optional | optional |  |

| Temperature sensors on air side farmpartner-tec |  |

|

|

| Additional feeding (heat / cold) |  |

|

|

| Redundant double pump |  |

|

|

basic

Basic Version

- Highly efficient, multi-step high-pressure centrifugal pump with inline connections. All pumps are equipped with a user-friendly mechanical seal in cartridge construction and a seal suitable for glycol for easy maintenance. At least IE3-standard motors (≥ 0,75 kW) with motor protection as cold conductor.

- Up to DN50: three-way valve with external thread, PN16, housing made of red brass, electromotive actuator.

- Membrane expansion tank with 10 bar maximal pressure and cap valve, approved up to 50 % frost protection.

- Piping sizes are determined by unit size.

- Larger than DN 50 on enquiry with modified housing dimensions.

- Up to DN50: strainer with sleeve connection in slanted design, PN16, exchangeable sieves by slanted design, installed in front of high-pressure centrifugal pump for optimal protection of pump components.

- Up to DN50: ball valve made of corrosion-proof red brass, PN10, ball valves before and after the pump for shut-off during maintenance.

| Nominal width [DN] |

Flow [m3/h] |

Pipe dimension [mm] |

Height [mm] |

Width [mm] |

Depth [mm] |

External pipe length (total max) [m] |

Pressure losses register (total max) [kPa] |

Base pump [kPa] |

| 20 | 1 | Ø 22x1,5 | 1000 | 1200 | 500 | 50 | 250 | 0,55 |

| 25 | 2 | Ø 28x1,5 | 1000 | 1200 | 500 | 50 | 250 | 1,1 |

| 32 | 3 | Ø 35x1,5 | 1000 | 1200 | 500 | 50 | 300 | 1,5 |

| 40 | 5 | Ø 42x1,5 | 1000 | 1200 | 500 | 50 | 300 | 2,2 |

| 50 | 8 | Ø 54x1,5 | 1000 | 1200 | 500 | 50 | 300 | 4,0 |

defrost

with integrated frost protection

- Highly efficient, multi-step high-pressure centrifugal pump with inline connections. All pumps are equipped with a user-friendly mechanical seal in cartridge construction and a seal suitable for glycol for easy maintenance. At least IE3-standard motors (≥ 0,75 kW) with motor protection as cold conductor.

- Frequency converter for stepless speed control of high-pressure centrifugal pumps. The converter is a com-plete unit with programming and operating unit with clear text unit and integrated repair switch.

- Up to DN50: three-way valve with external thread, PN16, housing made of red brass, electromotive actuator.

- Membrane expansion tank with 10 bar maximal pressure and cap valve, approved up to 50 % frost protection.

- Up to DN50: strainer with sleeve connection in slanted design, PN16, exchangeable sieves by slanted design, installed in front of the high-pressure centrifugal pump for optimal protection of pump components.

- Regulation integrated in frequency converter for easy control by 0-10V signal and release of GLT, integrated adjustment of frost protection by temperature sensor on water side and control of three-way valve.

- Up to DN50: ball valve made of corrosion-proof red brass, PN10, ball valves on exits of hydraulic module for shut-off during maintenance.

- Very compact construction for small place requirement in ventilation center

- Larger than DN50: on request, with modified housing dimensions.

| Nominal width [DN] |

Flow [m3/h] |

Pipe dimension [mm] |

Height [mm] |

Width [mm] |

Depth [mm] |

External pipe length (gesamt max) [m] |

Pressure losses register (gesamt max) [kPa] |

Base pump [kPa] |

| 20 | 1 | Ø 22x1,5 | 1000 | 1200 | 500 | 50 | 250 | 0,55 |

| 25 | 2 | Ø 28x1,5 | 1000 | 1200 | 500 | 50 | 250 | 1,1 |

| 32 | 3 | Ø 35x1,5 | 1000 | 1200 | 500 | 50 | 300 | 1,5 |

| 40 | 5 | Ø 42x1,5 | 1000 | 1200 | 500 | 50 | 300 | 2,2 |

| 50 | 8 | Ø 54x1,5 | 1000 | 1200 | 500 | 50 | 300 | 4,0 |

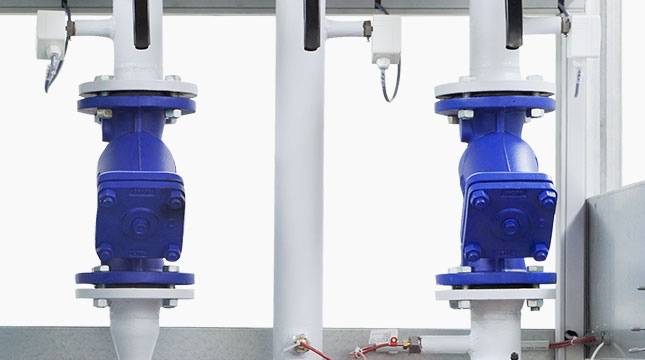

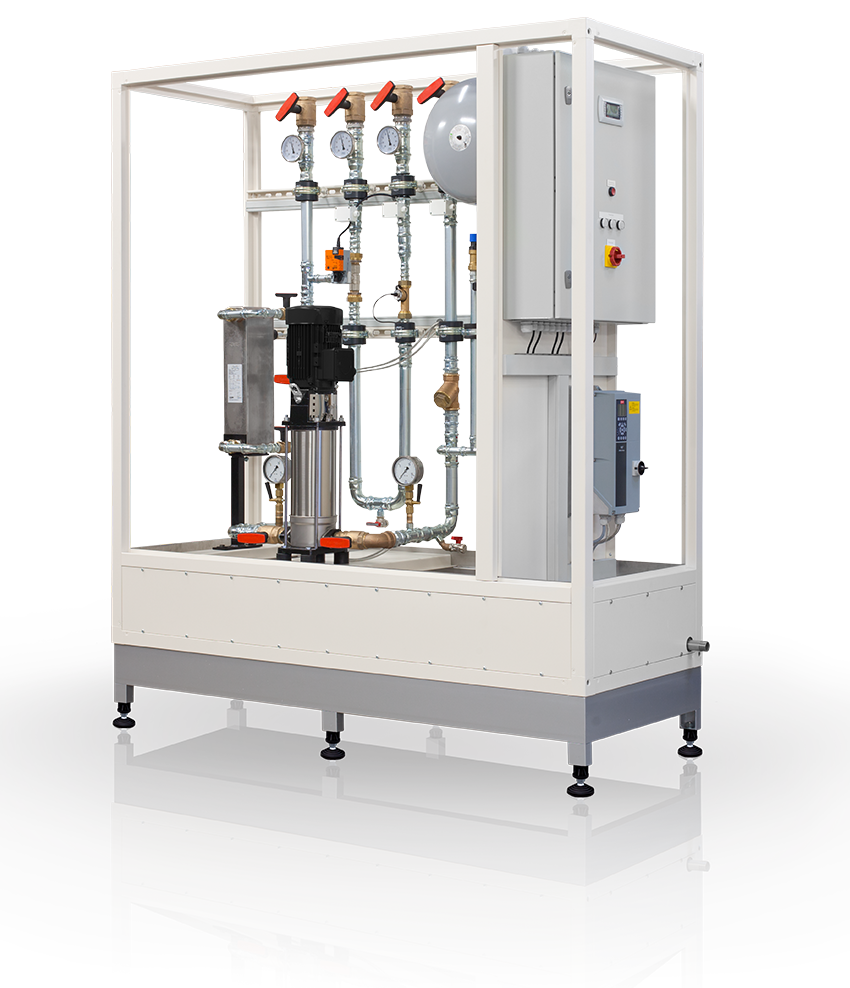

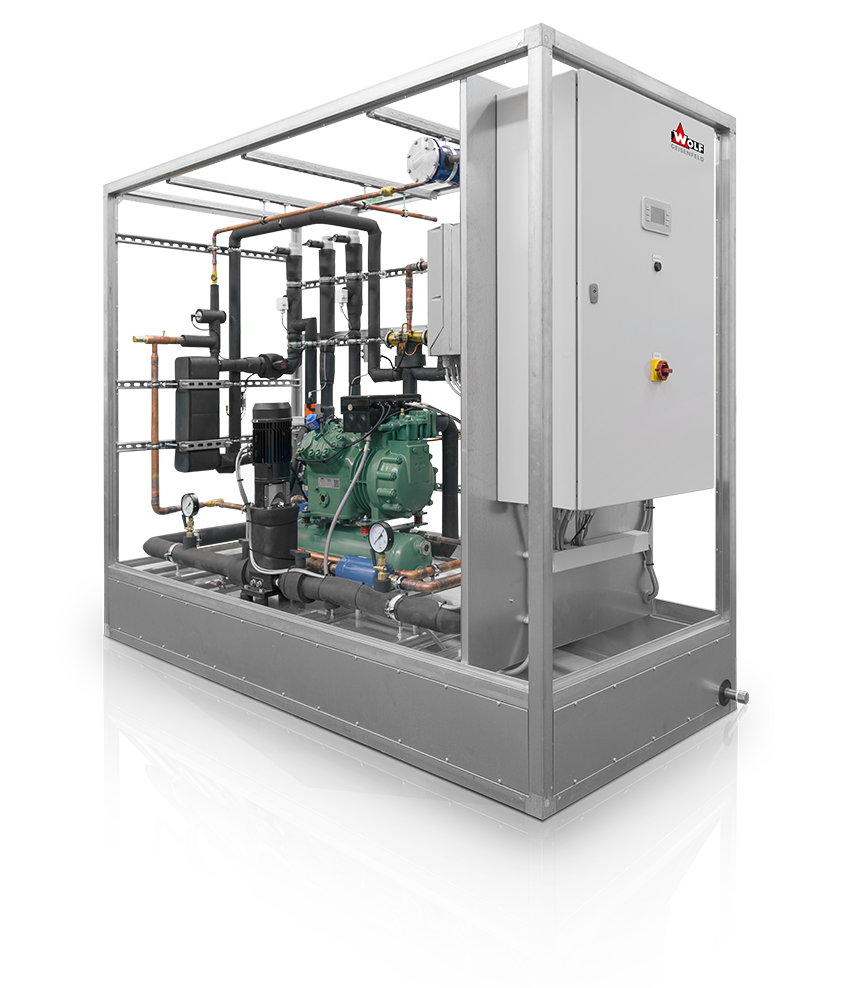

magna

The high-performance KVS

- Highly efficient, multi-step high-pressure centrifugal pump in vertical design with inline connections. All pumps are equipped with a user-friendly mechanical seal in cartridge construction and a seal suitable for glycol for easy maintenance. At least IE3-standard motors (≥ 0,75 kW) with motor protection as cold conductor.

- Frequency converter for stepless speed control of high-pressure centrifugal pumps. The converter is a com-plete unit with programming and operating unit with clear text unit and integrated repair switch.

- Up to DN50: three-way valve with external thread, PN16, housing made of red brass, electromotive actuator; from DN50 upwards: three-way valve with flange connection, PN16, valve housing in ductile cast, electro-motive actua-tor.

- Energy-optimal control system by freely programmable DDC-controller, adjustment of programming to the in-dividual requirements of the project, control via BACNet possible, permanent communication of operating conditions with GLT.

- Membrane expansion tank with 10 bar maximal pressure and cap valve, approved up to 50 % frost protection.

- Up to DN50: ball valve made of corrosion-proof red brass, PN10; from DN50 upwards: maintenance-free soft-seal intermediate flange shut-off flap with centering lugs, PN16, ball valves before the pump for shut-off during maintenance, additional ball valves on the exits of hydraulic module.

- Switchboard made of powder-coated sheet steel, DDC-controller installed in switchboard, 8-line display in switchboard door, inside lighting and socket 230V in switchboard, cable entry internal from below, external from above, door hinge right- or left-hand.

- By a constant supervision of the air inlet and outlet quantities by pressure sensors on the fan jet as well as temperatures before and after the registers, the heat recovery rate can be determined and the system always be operated in optimum efficiency.

- Up to DN50: strainer with sleeve connection in slanted design, PN16, exchangeable sieves by slanted design; from DN50 upwards: welded flange strainer, installed before the high-pressure centrifugal pump for optimal protection of pump components.

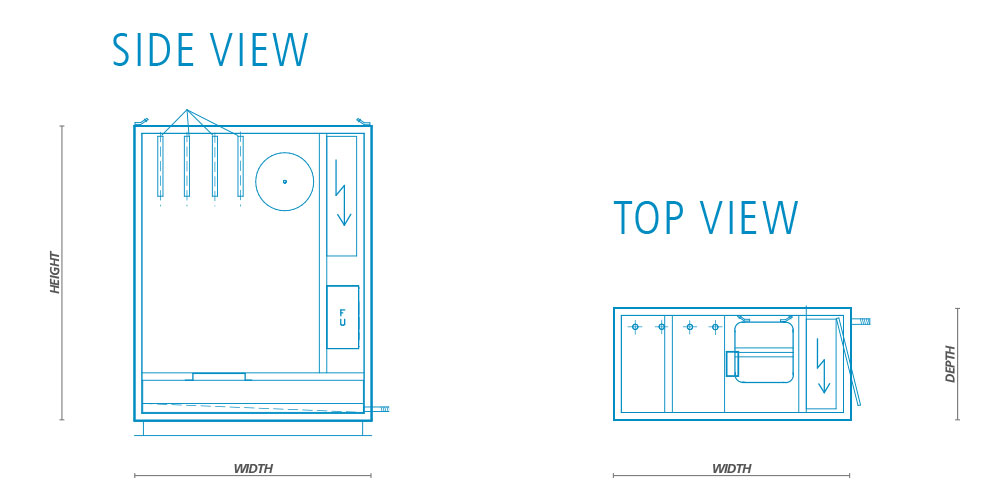

| Nominal width [DN] |

Flow [m3/h] |

Pipe dimension [mm] |

Base pump [kW] |

Height [mm] |

Width [mm] |

Depth [mm] |

Pipe length in this dimension (external total) [m] |

Pressure loss of all kVS-registers (total max) [kPa] |

| 20 | 1 | Ø 22x1,5 | 0,55 | 1950 | 1600 | 750 | 50 | 300 |

| 25 | 2 | Ø 28x1,5 | 1,1 | 1950 | 1600 | 750 | 50 | 300 |

| 32 | 3 | Ø 35x1,5 | 1,5 | 1950 | 1600 | 750 | 50 | 300 |

| 40 | 5 | Ø 42x1,5 | 2,2 | 1950 | 1600 | 750 | 50 | 300 |

| 50 | 8 | Ø 54x1,5 | 4,0 | 1950 | 1900 | 950 | 50 | 300 |

| DN 50 | 10 | Ø 58x1,55 | 5,5 | 1950 | 1900 | 950 | 100 | 300 |

| DN 65 | 15 | Ø 73x1,43 | 7,5 | 1950 | 1900 | 950 | 100 | 300 |

| DN 80 | 20 | Ø 85x1,4 | 9 | 2050 | 2550 | 1150 | 150 | 400 |

| DN 100 | 35 | Ø 110x1,4 | 11 | 2050 | 2550 | 1150 | 150 | 400 |

| DN 125 | 50 | Ø 134x1,33 | 15 | 2050 | 2550 | 1150 | 150 | 400 |

magna OPTIONS

for increased cold recovery. Improves cold recovery by an exhaust air humidifier before the register, so that significantly more energy can be recovered for cooling.

Armaflex system insulation

Insulation of all components and pipes inside the hydraulic unit with high-grade, division-tight Armaflex insulation.

Piping in stainless steel

High-grade piping made of INOX-stainless steel and pump housing made of AISI304 stainless steel.

Weatherproof housing for outdoor installation

Complete housing in resistant design.

The roof is glued with a special, 2,8 mm thick, UV-proof plastic foil and has got a drip edge all around.

magna HP

The high efficiency run around coil system with integrated heat pump

- Pre-assembled and internally wired unit for quick and easy installation on site

- Integrated and capacity-controllable reversible heat pump (R513A, GWP 613.4)

- Independent and functionally self-contained overall system.

- Project-specifically defined, controlled and demand-optimised generation and shifting of heating and cooling capacity. The required conditioning of the supply air is ensured without any additional heating and cooling energy on the building side.

- Reversible heat pump matched to the total heating and cooling demand and integrated in the HKV system. Reversible heat pump integrated in the high efficiency run around coil system. Temperature transfer efficiency > 90 %!

- Highly efficient, multi-step high-pressure centrifugal pump in

vertical design with inline connections; All pumps are equipped with a user-friendly mechanical seal in cartridge construction and a seal suitable for glycol for easy maintenance; At least IE3-standard motors ( 0,75 kW) with motor protection as cold conductor - Up to DN50: three-way valve with external thread, PN16, housing made of red brass, electromotive actuator; from DN50 upwards: three-way valve with flange connection, PN16, valve housing in ductile cast, electro-motive actuator

- Up to DN50: ball valve made of corrosion-proof red brass, PN10; from DN50 upwards: maintenance-free soft-seal intermediate flange shut-off flap with centering lugs, PN16, ball valves before the pump for shut-off during maintenance, additional ball valves on the exits of hydraulic module

- Up to DN50: strainer with sleeve connection in slanted design, PN16, exchangeable sieves by slanted design; from DN50 up-wards: welded flange strainer, installed before the high-pressure centrifugal pump for optimal protection of pump components

- Membrane expansion tank with 10 bar maximal pressure and cap valve, approved up to 50 % frost protection

- Glycol collecting tray with 1“ connection for collecting of the entire glycol mixture in leakage case

- Frequency converter for stepless speed control of high-pressure centrifugal pumps; The converter is a complete unit with programming and operating unit with clear text unit and integrated repair switch

- Energy optimised regulation controls by a free-programmed DDC controller, adjustment of the programming to the respective project requirements, regulation via BACnet or Modbus possible, continuous communication of the operating states with the BMS

- Switchboard made of powder-coated sheet steel, DDC-controller installed in switchboard, 8-line display in switchboard door, inside lighting and socket 230V in switchboard, cable entry internal from below, external from above, door hinge right- or left-hand

- The system can be operated at optimum efficiency level thanks to continuous flow rate monitoring of the supply and extraction air (by means of pressure cells in the fan nozzle), as well as to monitoring of the fluid volume flow rate in the hydraulic unit

Advantages

- energy-optimized efficiency control

- electronic flow measurement

- Performance adjustment to supply and return air flows

- Many possibilities

- Adjustable, periodical pump run for keeping free the pump seat when unit not in use.

- Integrated frost protection control for keeping free the coils and for efficient working of the run around coil system

- Freely programmed DDC-control with display and fault message as plain text display

- No additional external cooling or heating required

- Reduction of interfaces, hydraulics and I&C

- Saving unit length

Freely programmed DDC-control and control panel with plain text display

magna HP OPTIONS

① for a higher cold recovery and electric cold power reduction for the supply air conditionning. Improves the cold recovery by means of a return air humidifier before the coil with driven from the Therm-Connect magna control. Hence, the integrated heat pump can be designed smaller and used in an energy-optimised way.