Quality Guarantee

Weatherproof Air Handling Units

Our weatherproof air handling units of the series WK-com belong to the most silent air handling units worldwide. Available are various cover variants from 30 mm up to 110 mm, even more if necessary.

The interior cover is non inflammable A2, the outer cover hardly inflammable B1.

The roof is covered with a 2.8 mm thick UV-resistant plastic special foil and equipped with a dripping rim all around.

Hygienic Air Handling Units

As with all WK-com units, the interior is uncompromisingly hygienically smooth and can be cleaned without leaving any residue and is designed for wipe disinfection. All surfaces, seals and sealing materials are disinfectant-resistant and absolutely smooth. Corners and joints are additionally grouted with tested sealants. Robust and germ-inhibiting materials such as stainless steel (V2A) or aluminium (AlMg3) are used in the interior, coated versions are also available.

Hygiene from the Professionals

For the use of AHUs in operating rooms, laboratories, clean rooms and hospitals, special requirements have to be considered. They are the lungs of the building and supply their people and processes with hygienically clean and comfortable fresh air. This represents a high degree of responsibility for ensuring consistent quality.

WOLF air handling units in hygienic design meet the highest hygienic, energetic and structural requirements. Consistent compliance with all relevant standards and guidelines, especially DIN EN 1946-4, DIN EN 13053 and VDI 3803-1 is ensured. For sensitive areas such as surgery rooms, clean rooms, hospitals or laboratories, our WK-com in hygienic design is the first choice.

All materials used, such as gaskets, sealants and built-in parts are certified for use with high hygiene requirements. Regular tests carried out by independent institutes such as TÜV Süd or the Institute for Air Hygiene ILH Berlin confirm the perfect compliance with all valid hygiene requirements.

Experience WOLF hygiene technology in 360 degrees:

Swimming Pool Air Handling Units

Challenges in the Swimming Pool Area

Standard air handling units are overwhelmed with the special requirements in the swimming pool and spa are. Here the feeling of comfort and health of the bathers have first priority.

In addition, the air handling units have to meet the current technical standards and ensure reliability and efficiency.

Therefore WOLF engineers have specially designed a swimming pool design for these specific tasks:

WK-com N / S / H - Swimming Pool

Nothing Is Lost in This Cycle

Swimming pools and spa baths are especially energy-intensive buildings, they offer because of this fact numerous opportunities for energy-saving and energy-recovering measures.

Energy that is used for dehumidification is given back with our optimized systems to 100 percent to the swimming pool area.

Overruns from this recovery can be used to heat the pool water.

ATEX Design

WOLF ATEX Units are available in all sizes and designs

- Indoor assembly

- Outdoor assembly

- Hygiene design

- Combined units

- with MSR-technology.aufstellung

Highest Safety even in explosive Atmospher

RLT-units placed in explosive atmosphere or delivering explosive air are subject to special requirements which have to be definitely and proven observed by operator, planner, constructor and manufacturer. Starting point is a risk assessment and classification by builder or operator acc. to ATEX-Guideline 1999/92/EG (ATEX 137).

WOLF-ATEX units are planned, produced and individually tested by WOLF-specialists acc. to these directives and legal regulations of ATEX-Guideline 94/9/EG.

Selection of certified components, setup and assembly by especially trained experts, individual approval and inspection of each unit as well as check and supervision by TÜV Süd provide highest safety to our partners.

All three types N, S and H comply with the requirements for ATEX-designs. Together with our customers, we have designed and built ATEX-units for indoor and outdoor assembly even for hard usage on offshore oil rigs or in Russian steppe.

Permanent individual TÜV-approvals confirm the high quality and accurate observation of the high requirements.

V4A model

acid- and alkali-resistant, for offshore use as well.

Some working environments for air handling units place much greater demands on surfaces that cannot be addressed by galvanization or wet paint/powder coating.

The use of stainless steel is indispensable in cases where the atmosphere inside or outside the appliance is corrosive. WOLF has extensive experience with air handling units that are either partially or completely constructed of V2A or even V4A cladding and has already delivered many units that have proven themselves in these types of hostile environments.

Wolf is often tasked with delivering air handling units with stainless steel cladding for offshore use as well. Modular and flexible design enables a wide variety of bespoke solutions: Depending on requirements, the entire inside cladding can be executed in stainless steel, or only part of the unit. Similarly, it is a simple matter to construct only the external cladding from V2A or V4A. What is important here is that our specialists identify the precise requirements in collaboration with the customer in order to configure the air handling unit precisely for the application in question.

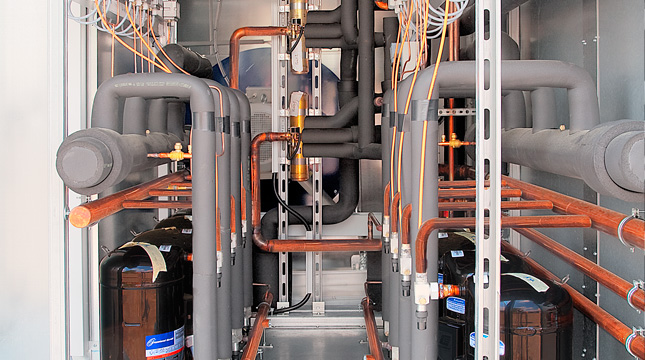

Cooling Systems

Direct Cooling

The air flow is cooled directly, the refrigerant evaporator is lying directly in the air flow to be cooled. Therefore, this kind of refrigerator is called air cooler.

Advantages

- low investment

- low space requirement

- low operating costs

- high flexibility in erection

- low planning expenditure

- few services to be provided by customer

- no water problems (freezing danger, glycol concentration, corrosion)

- saving of equipment like recirculating pumps, cooling water circuit, cold water set, cold water circuit, storage and extension vessels, ventilating and emptying installations, pipe installations etc.

- low distribution losses

- high total efficiency

- good de-humidification capacity

Indirect Cooling

The water is colled in the refrigerant evaporator, the circulating water serves for cooling the air flows by further heat exchangers. This refrigerator is a water refrigerator.

Advantages

- regulating circuits of air-conditioning unit and refrigerator largely separated

- regulation is controlling cold water throughput by air cooler

- refrigerator regulation is keeping cold water temperature approx. constant

- cold and warm water distribution systems are identical and thus familiar to technician

- clear separation of performance guarantees between air-conditioning and refrigeration technology

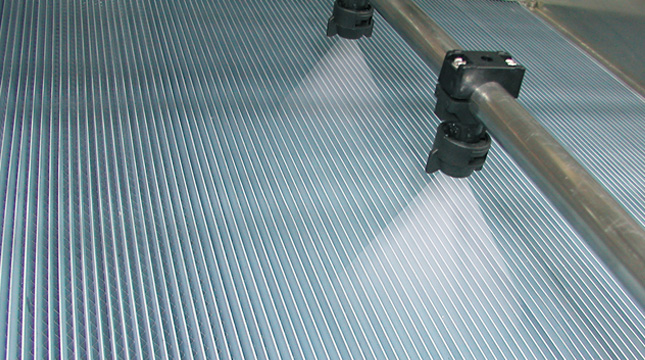

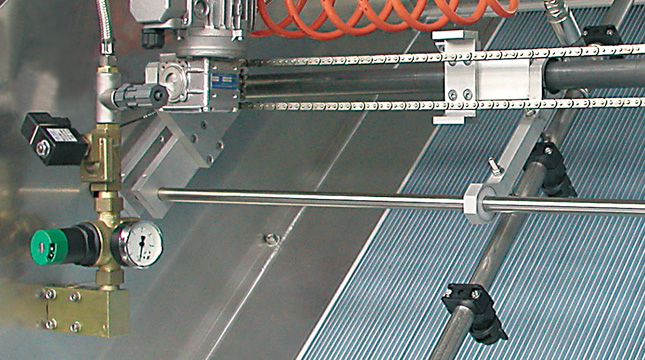

Adiabatic Cooling

Plate heat exchanger for refrigerant-free supply air cooling (gentle cooling)

By the adiabatic cooling (indirectly evaporative), a cooling of around 10 °C (for example from 32 °C to 22 °C) can be reached environmentally friendly, without cold compressor and without refrigerant.

The operating costs of such a plant are about 50 % lower than those of a plant with conventional technology.

Advantages

- cooling in summer, heat recovery in winter

- extremely low maintenance required

- manageable technology

- secured hygiene in case of correct operation

- minimal construction length

- to be installed into plants from 2000 m³/h air quantity on

- massive energy savings - up to 40 % compared to conventional plants with mechanical coldness!

- optimized water consumption: Residual water quantities of less than 15 %

- environmentally friendly: no refrigerants, no FCKW

- infinitely variable

Comfort Combination

Air-conditioning unit with upstream adiabatic cooling and downstream cold unit (air cooling) with regulation.

By the plate heat exchanger, a unit can be used for heat recovery in winter and for cooling the supply air in summer.

Advantages

- no or minimal refrigerant use

- low investment costs by double benefit (summer/winter)

- electric power input is reduced