Spray Booths for Commercial Vehicles and Industry

Wet Paint Coating Systems for Industry and Craft

Highest level in Equipment & Quality

Excellent surface quality, perfect protection against corrosion and outstanding optics are marking first-class products not only for spraying passenger cars, but also for commercial vehicles and mechanical engineering.

Competence by Experience

Having realized a great number of large spray booths in Germany and abroad, WOLF has become a preferred partner in commercial vehicles, agricultural and construction machine sector. Also in general mechanical engineering, WOLF-spray booths are standing for highest quality and most modern technology.

Customer-specific Solutions for any Demand

If semi-trucks, mechanical engineering, construction machines, boats or wind turbines - WOLF offers you the solution to your requirements by own planning and production.

We are planning for you exactly the booth technology you need to realize your aims.

Highest reliability, easy handling, maximal energy efficiency and attractive appearance are always the basic features of the installed booths.

Benefits

- Competence in planning and construction

- Renowned manufacturer of air-conditioning and ventilation plants

- High production depth on maximal quality level

- Own control system construction

- Strong and reliable service

- Best references in automotive and paint industry, institutes and training sector

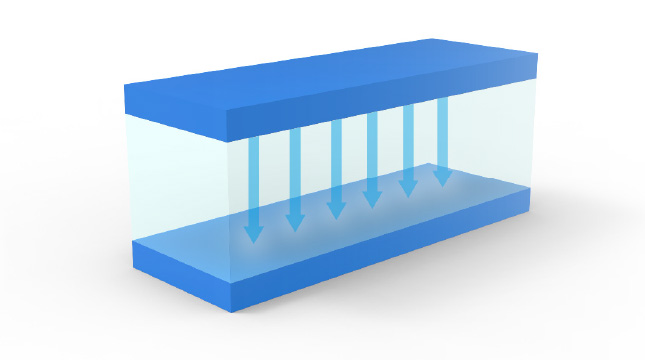

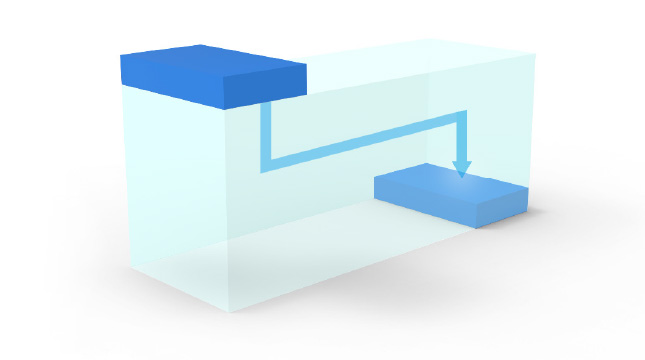

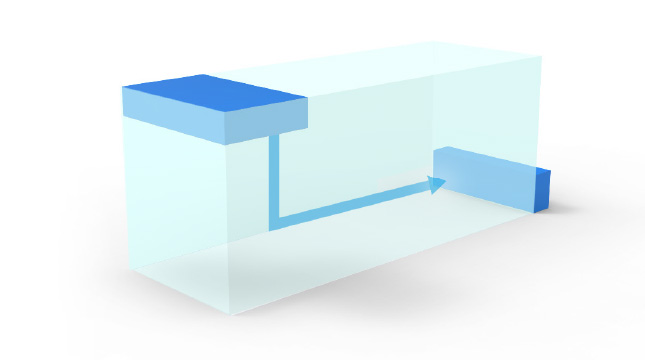

Ventilation variants

vertical with floor extraction

vertical with sectional ventilation

diagonal with floor extraction

diagonal with extraction wall

The highest level of energy efficiency

optimized

As a manufacturer of ventilation and air-conditioning plants, WOLF is able to conceive even booths with complex airflow requirements, so that your spray booth is completely “one-stop” and 100 percent optimized – also regarding energy consumption.

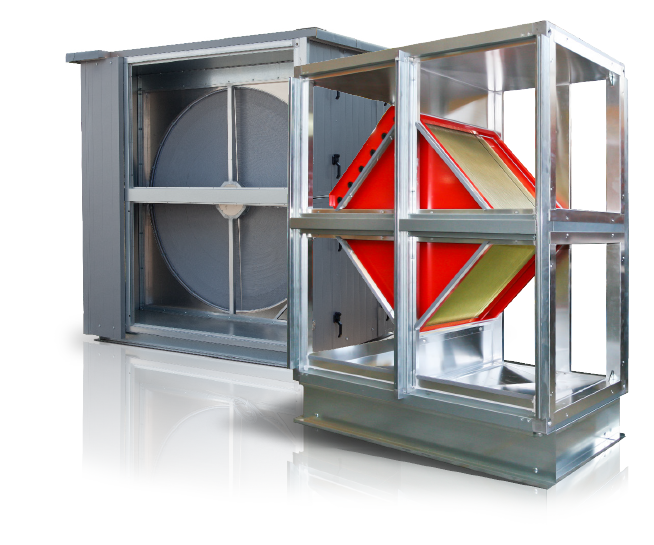

Air technology and heat recovery

One of the great advantages of WOLF is the wide ventilation and air-conditioning program by own production, providing the optimal conception for nearly any requirements.

Essential is, for example, the right selection and dimensioning of heat recovery systems. In most cases, the approved plate exchanger modules are used. If also humidity is to be transferred, highly efficient rotary heat exchangers are used.

Heating is ideally done with hot water, which is generated for example by a CHP unit or a heat pump. However, it can still be heated conventionally with gas or oil. Optionally, the supply air can be equipped with a cooling function, which ensures a pleasant indoor climate in view of ever-increasing summer temperatures.

Control system and regulation

Modern mode programs are controlling the optimal energy consumption for each kind of operation such as cleaning, spraying, evaporating and drying. Single sections in large booths can be switched, so that only the respective zone where paintwork is done is run with full air capacity.

Spray booth commercial vehicles

State-of-the-art spraying hall for commercial vehicles

WOLF Reference

A large spray booth with a length of 21,5 m as well as two preparation bays of 17 m, each, provide not only the requirements for large-scale paintwork, but also the basics for optimal working processes.

If trucks, buses, caravans or industrial machines – nearly any size can be painted in the new paint shop in an adjusted area with efficient energy consumption. The spray booth can be divided into a 14,5 m and a 7 m section. In the large section, buses or commercial vehicles are painted, while the last third is separated.

The smaller booth section is mostly used for painting the numerous single parts of commercial vehicles.

On the optionally equipped preparation bays, also big vehicles can be treated completely and without manoeuvring. Each preparation bay has got a 2-zone-switching with vertical air guidance, so that only one zone or both of them can be ventilated as required.

A further advantage is the heating as well as ventilation and deaeration of the hall by the machinery of the preparation bays.

Spray booth commercial vehicles

Perfect corrosion protection

WOLF Reference

The requirements for corrosion protection of vehicles are increasing – also for large heavy-duty low-loaders. In order to meet these requirements, the paint shop of a vehicle manufacturer was completely reequipped. A total of four booths, each with a size of 22,0 x 6,0 x 5,0 m (L x W x H), were built up – two of which are spray booths, one for sandblasting and one for zinc spraying. When zinc is applied in arc process, fine zinc dust is produced, which must be reliably extracted, since it is both flammable and explosive.

Therefore, the necessary dust filter system has got explosion protection flaps and rupture discs. Smooth surfaces on booth inside walls prevent deposits and can easily be cleaned. The two spraying/drying booths are equipped with a sectional ventilation. Only in the area where spraying is just being done, three of the eight sections are actively ventilated and exhausted. In this way,

the air volume of the booth and thus the energy requirement can be reduced by over 60%.

Spray booth special parts

Open-space spray booth for big steel constructions

WOLF Reference

The spraying zone is 24 m long and wide, subdivided into 8 working bays with 10 x 5 m, each. Each of them can separately be ventilated on site. The whole spraying zone is covered by filter ceilings.

The paint mist is extracted by paint mist separation mats, arranged below the gratings of the working bays.

The booth is rated so that paintwork can be done on two working fields at the same time. Inlet air flows into the filter ceiling over the selected zone, outlet air is extracted into the floor ducts of the zone. The booth is ventilated by two powerful combined air inlet / outlet machineries. The booths are equipped with a heat recovery system.

Spray booth construction machinery

Above-floor large-space spray booth

WOLF Reference

Where excavator blades could cause damage to cables or pipes, suction excavators are increasingly being used. They simply suck away the loosened soil like a huge vacuum cleaner. In a large-space spray booth with 11,0 x 5,5 x 4,5 m (L x W x H), both the single parts of the suction excavator and the completely assembled truck frames are painted.

For drying, the painted parts are put into a separate dryer same size as the spray booth. Since no foundation pits could be created being close to a river, both the spray booth and the dryer have got lateral wall extractions. The VARIO heat recovery of the ventilation units, which can be used throughout the year, significantly contributes to energy saving.

Spray booth mechanical engineering

Top level industrial coating

WOLF Reference

For the leading manufacturer of high-density canned motor pumps near Freiburg, a complete paint hall was optimally designed.

The spray booth consists of two areas: large-space booths for heavy special pumps up to 10.000 kg and a conveyor system for serial pumps up to 500 kg.

The fully assembled heavy pumps are degreased in a washing booth by a high-pressure cleaner. For drying, the ventilation system can be switched to circulating air operation and the temperature can be increased. The large parts are then coated in a spraying/drying booth with 7 x 5 x 5 m (L x W x H).

The large-space booths are equipped with electric chain hoists for lifting the parts. To be able to paint safely from below, the load bar is suspended form-fitted.

The fully assembled serial pumps pass the painting process from degreasing - drying of adhesive water - painting - evaporating - drying in a conveyor system with manual sliding system.

The plant can be retrofitted with a Power & Free conveyor system, if required.

Spray booth boat building

Fine wood in full splendour

WOLF Reference

In a shipyard on the shores of Lake Constance, elegant wooden sailing boats are painted high-gloss in a WOLF large-space spray booth. The inside dimensions of the booth are 18,0 x 6,0 x 5,0 m (L x W x H). In order to consume as little energy as possible, the booth has got a sectional ventilation with four extraction zones, requiring a significantly lower air capacity than conventional spray booths. In the case of floods, the level of Lake Constance may rise to the spray booth site. Therefore, it stands on a concrete base, and paint mist extraction takes place by lateral extraction walls above the base. Since painting with a spray gun is being done only above the waterline, there are no disadvantages due to sidewall extraction. A particular challenge was the exact fitting of the booth into the roof structure of the building to be able to make full use of the hall height.

Spray booth contract coating

By the hall crane directly into the booth

WOLF Reference

One of Germany’s biggest contract coaters has expanded his capacities for wet painting of large parts by 2 large-space booths of 15,0 x 6,0 x 4,7 m (L x W x H) each. Mainly power heads for rail vehicles and masts for wind turbines are painted.

In order to be able to place the heavy components by the hall crane directly in the booths, each of them has got 10,0 m long slots in the booth ceiling. The slots can be closed by a horizontal roller blind, so that a controlled air balance in the booth is ensured.

Spray booth agricultural machinery

Small but nice

WOLF Reference

At an attachment manufacturer for landscape maintenance, a small spray booth with manual suspension conveyor has been installed.

It allows an easy handling of the components within the booth, with the parts being hung up and down in front of the sliding gate.

The plant was placed on the even hall floor without any foundation work. Paint mist extraction is done by an extraction wall with dry separation.

Spray booth gear motors

Circular conveyor in smallest space

WOLF Reference

Some gear motors have to be painted in small quantities in the colour requested by customer. In order to do this as efficiently as possible, a small spray booth with Power & Free circular conveyor was installed.

The components are suspended at a lowering station of the loading and unloading point, manually pushed until they are taken over by the automatic conveyor and automatically pass two lanes through the spray booth and the dryer.

In the spray booth, two painters can work at the same time and specify the working cycle individually. The finished parts are either taken off at the discharge point or pass the plant for a second paint coat. Here is a separate branch.

The plant was installed on the even hall floor, no foundation work was required.

Spray booth hall construction

Extraction follows the painter

WOLF Reference

When long steel beams are coated, it makes little sense to extract the paint mist even where no spraying is being done. It is better to have a ventilation only in the really necessary place. The significantly lower air capacity reduces energy consumption and saves investment costs. A specialist in hall construction made of steel and wood applies a fire protection coating on the steel beams already in the factory. The beams are placed by the hall crane in a 25 m long spraying area which is open to the top.

The painter is wearing a transmitter on his belt, which is detected by several aerials, so that the plant knows precisely his position.

The paint mist is always extracted in the right place without the painter having to press a button.

Your Request, our Service – we are on site with you

The WOLF service team is organised decentrally. Our specially trained service engineers start their tours from various fixed locations in Germany.

The customer service centre in Geisenfeld is where all ends meet. Deployment and timing are planned for a smooth flow. This organisation structure ensures a cost-effective service with fastest response time.