TAIFUNO® vision Spray Booth

The High-Tech Spray Booth

Intelligent energy management and efficient heat recovery systems are the key components of operating costs.

TAIFUNO®vision - the premium brand stands for this..

Advantages

- most modern control technology

- intelligent energy management

- maximal energy efficiency

- high ease of use

- absolute process security

- own production

- finish quality according to WOLF quality standards

- long lifecycle

- care of environment

- lowest operating costs

- first-class WOLF-service

The intelligent and efficient Spray Booth

TAIFUNO® is the worldwide renowned top product in the range of spraying and drying booths - synonymous for high-class technology, quality and energy efficiency.

The experience gained by more than 1800 realized TAIFUNO®-booths and consistent developing work mark the current standard of booth technology."

TAIFUNO®vision is the new generation of TAIFUNO® spray booths. Future technologies like Red-Eye® for recording the object temperature, VARIO©HR - the dynamic heat recovery around the year or the integration of alternative energies make TAIFUNO®vision to a premium-class high-tech product.

The TAIFUNO® -technology is conducted by a highly modern control system.

The multitude of functions is unified in a central station, functional and easy to survey. The user friendly control system is very easy to handle."

Control System

Intuitive to handle

With the new, expansible control system of TAIFUNO®vision, you have the future technology fully under control.

Your are being led safely through the working process.

- without manual

- without long instruction

- once explained and you are fit

Intelligent Energy Management

- process navigation system

- automatic connection of operating modes

- dynamic, temperature-controlled heat recovery*

- Red-Eye® Process control* and -visualization in Online-layout

- programme-controlled ventilating processes

- programm-controlled drying processes

- Automatic Standby-System

- Automatic Energy-Saving

- energy evaluation and operating costs recording*

Online Connection*

Each TAIFUNO®vision is equipped for connection to the WOLF-owned Service-Center. We only need your internet connection at our switchboard.

In case of a failure, experienced specialists in our headquarters do a first check „online“. Quickly and professionally - saving time and money.

So don't worry if you are far away from us.

Mode Lamp

With the Mode Lamp, even from a distance you have under control if your employees are using the efficient booth technology optimally.

In the modes of operation Cleaning, Spraying, Evaporating, Drying, Cooling and Energy-Saving, the lamp in the respective colour is shining. When Multi-Air is switched on additionally, the signal lamp is flashing.

Automatic Standby-System

This energy-saving function puts TAIFUNO®vision automatically to a reduced air and heating capacity, when in mode of operation Spraying the spray gun is not actuated. When actuating again, the full capacity is reached again within few seconds.

* optional

Multi-Air

The ultimate Evaporation System

The Multi-Air System is integrated between filter ceiling and lighting. The jets are installed sunk in the inclined side cladding; their blasting direction can be adjusted individually.

The Multi-Air System provides maximal process acceleration when evaporating and drying.

Time Saving

Immense time saving

Time saving is up to 70% compared to the method without Multi-Air. A partial flow of process air is acting as accelerator flowing at high speed out of the jets downwards and producing a turbulent flow around the object.

Automatic Evaporation

The TAIFUNO®vision control system offers you various evaporating programmes.

The software also includes special evaporating programmes which are pre-adjusted in coordination with the leading paint manufacturers, simplifying considerably the use of water paints.

With these automatic programmes, the parameters temperature, air exit velocity and time are optimally adjusted to the respective paint, guaranteeing a maximum of process security.

Red-Eye

New Drying Technology acc. to Object Temperature

By Red-Eye® technology, drying in a combi-booth is newly defined. The system is marked by two decisive advantages: high process security and a clear reduction of heating costs.

During Red-Eye® process, a laser-beam supported infrared temperature sensor is directed to the object by the multiple-axle swivel arm.

The heating installation is now regulated exactly according to the current object temperature which is permanently compared to the nominal value. The booth is heating only to the temperature actually required by the object / the paint.

drying costs can be saved

Maximale Einsparung durch Red-Eye® und Multi-Air

By the combination Red-Eye® and Multi-Air, up to 45 % of drying costs can be saved. Depending on the programme adjusted, the Multi-Air System is switched on immediately or after a certain delay.

The advantages of the Multi-Air-System in drying process are very well-known. Multi-Air is leading the warm air much more quickly and evenly to the object.

The temperature differents between upper and lower components is only minimal.

Therefore, the recirculating air temperature can still be decreased moreover, the recirculating air quantity is automatically reduced as soon as the object temperature is reached."

Heating not a degree too much, not a minute too long!

Light Evolution©

WOLF LED-Technology

An optimal lighting in the working range is absolutely necessary for perfect surfaces, providing optimal color matching and fine nuances as well as working with best light conditions.

The innovative booth lighting Light Evolution© with LED-technology offers you an energy-saving operation and a much better and more comfortable working light compared to a conventional lighting.

Light Evolution© is the system which assures energy-saving, best lighting conditions in the booth and thus an optimal paint quality. A retrofit is possible in all WOLF - booths without any problems.

saving potential

Saving power with Light Evolution© 70%

This reduction is due to a basically lower power consumption of LEDs. The decisive factor is the integration of Light Evolution© into the mode control of the spray booth TAIFUNO®vision: The lighting is permanently automatically adjusted to the process steps - it is integrated into the sprayer's normal working process.

The correct use of the technology is secured.

The WOLF Heat Recovery

Your Profit Zone

Heat Recovery in all Modes of Operation

The classic Heat Recovery (HR) systems for spray booths are only in function during spraying. During drying, the warm exhaust air (up to 100 °C) is blown outside unused.

The TAIFUNO®vision puts an end to this waste of energy. The heat recovery is fully in function in all modes of operation.

Dynamic VARIO©HR

A new development by WOLF is the Dynamic Heat Recovery. So far, the plate heat exchangers have to be removed from one booth in summer in order to avoid undesired high booth temperatures. Thus, on cold summer days or in cooler morning hours, the HR cannot be used. With the dynamic VARIO©HR*, the heat exchanger remains in the booth. The air flow is only led through the heat exchanger, when the booth control signalizes heat requirement. When no heat is required, the air is automatically flowing past the HR.

A further advantage of VARIO©HR is the spontaneous availability of the HR. Even when in spraying operation at high outside temperatures the air flow is led past the HR, there is high heat requirement during subsequent drying. The control system recognizes this and automatically switches to heat recovery immediately. You are saving energy even in summer around the clock.

Saving Heating Capacity by HR

Heating energy consumption of a combi-booth in % per year.

Comparison valid at a mean annual temperature of 9 °C

active: October to May

removed: June to September 51%

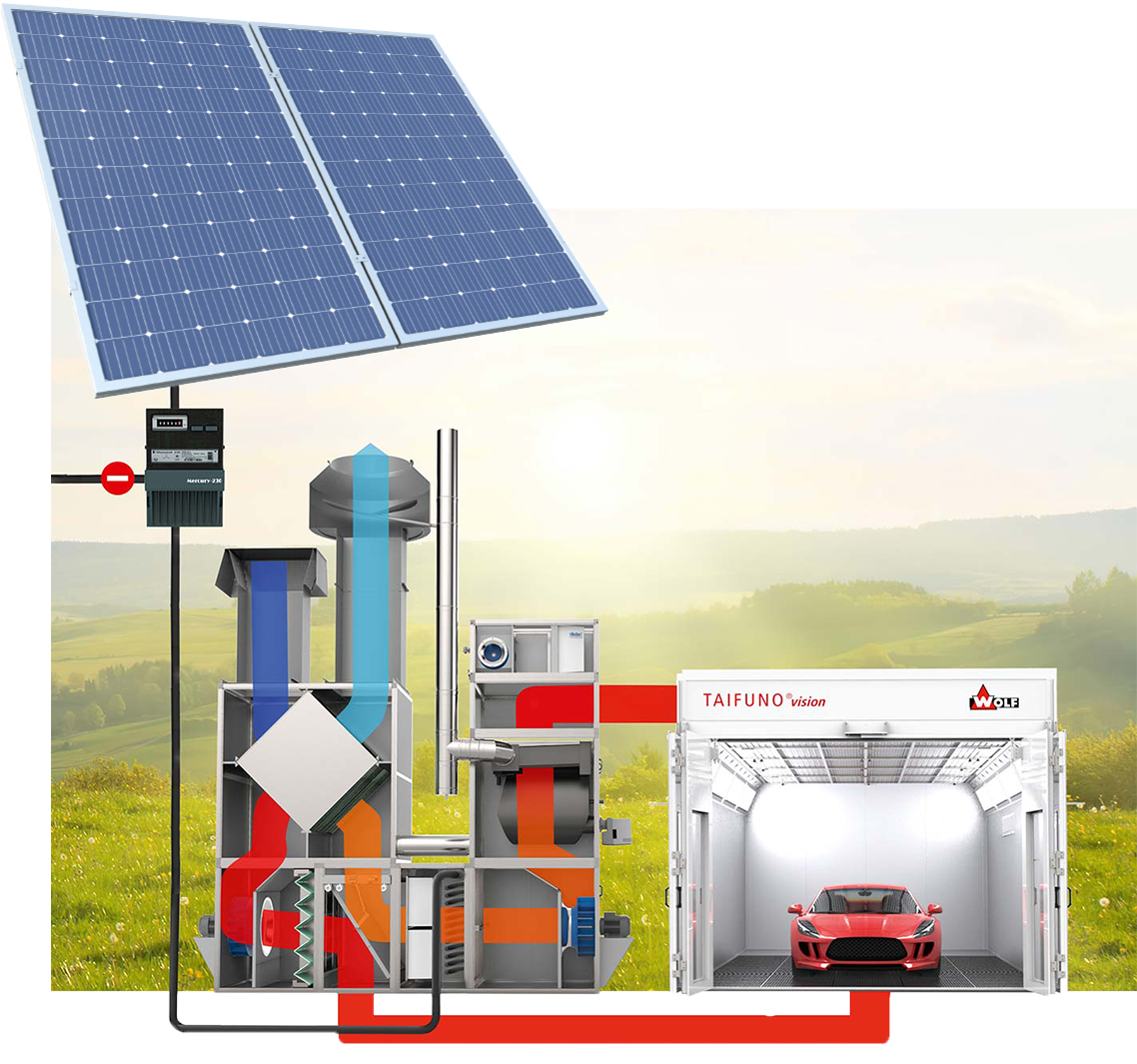

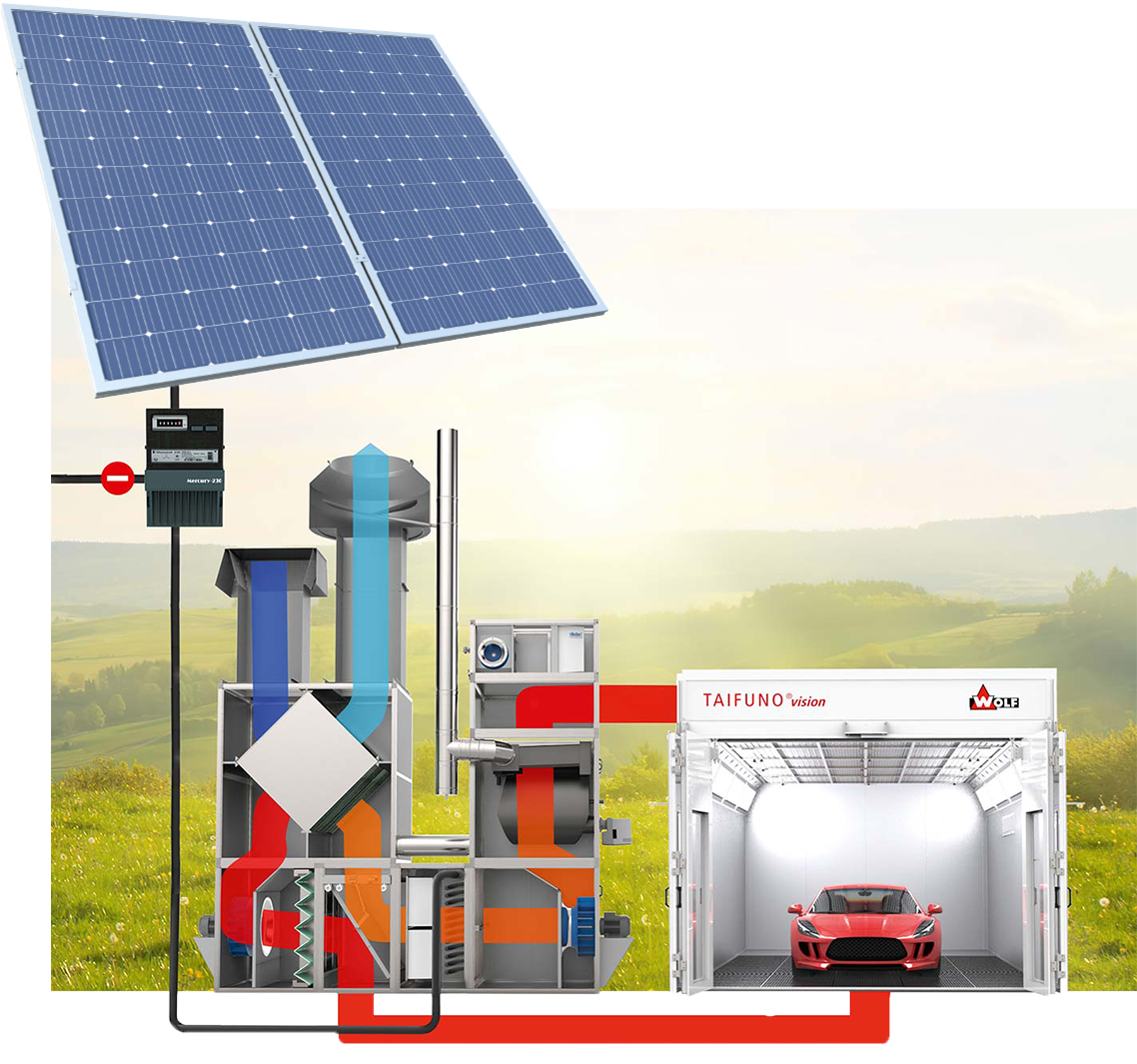

WOLF Green Technology

Alternative energies and existing waste heat, for example from block heating power stations, pellets heatings or solar thermals, can be integrated into machinery technology as a warm water circuit.

In most cases, these energy forms are used as supporting heating for an oil or gas heating. At low expense, the primary energy consumption can be reduced drastically.

Our engineers are kindly prepared to support you in your planning.

WOLF WLE-S Hybrid

HEAT ELECTRICALLY

WHEN THE SUN IS SHINING!

The ventilation unit WLE-S Hybrid has an additional electrical heater that is operated with electricity from a PV system. This unit only heats electrically if there is a surplus of selfgenerated electricity. The WLE-S Hybrid system affords a big contribution to the sustainability in a company.

- The performance of the heater will be adjusted to the size of the PV system

- Intelligent energy management of the system control

- Particularly efficient in the transitional seasons

- The retrofitting in existing systems is possible

WOLF WLE-S Hybrid

HEAT ELECTRICALLY

WHEN THE SUN IS SHINING!

The ventilation unit WLE-S Hybrid has an additional electrical heater that is operated with electricity from a PV system. This unit only heats electrically if there is a surplus of selfgenerated electricity. The WLE-S Hybrid system affords a big contribution to the sustainability in a company.

- The performance of the heater will be adjusted to the size of the PV system

- Intelligent energy management of the system control

- Particularly efficient in the transitional seasons

- The retrofitting in existing systems is possible